Vermiculite

Mineralogical

Vermiculite is one of the clay minerals. Vermiculite is an aluminium-iron-magnesium-silicate, which belongs to the mica group because it is has a similar structure and appearance and forms flaky crystals in the same way. The name of the vermiculite mineral comes from the Latin word vermiculus: "little worm".

Structure and manufacturing process

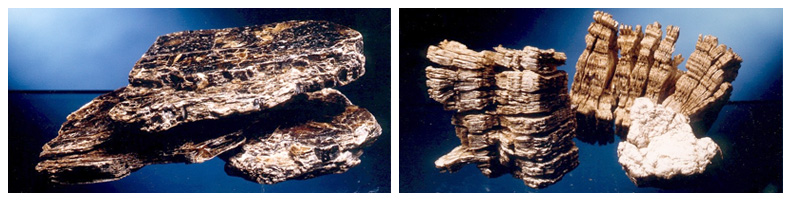

Raw vermiculite consists of thin, flat little plates. The exfoliation (expansion) takes place at a high temperature (800 - 1000 °C) without adding other substances. With the produced water vapour (reduction of the crystal water), the individual layers of the structure are forced apart. The volume of the vermiculite particles hereby enlarge by around 20 times. Expanded vermiculite is produced in various grain sizes.

Properties

| pH-value | ca. 7,5 |

|---|---|

| Sintering temperature | approx. 1,315° C |

| Melting point | approx. 1,315° C |

| Humidity | 1 - 1.5% after expansion |

| Trade hygiene | no silicosis danger |

| Non-flammable | class A1 according to DIN 4102 |

| Thermal conductivity | 0.07 W/mK according to DIN 4108 |

Thermal conductivity figures

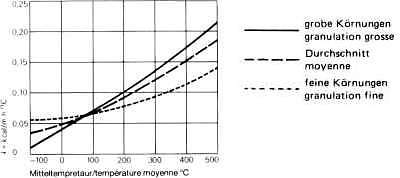

The following diagram shows the thermal conductivity figures of vermiculite granulations at -100°C to +500°C average temperature. At higher temperatures, due to the stronger temperature flow (convection), a smaller granulation is recommended. However, you can reduce the thermal flow when using coarser granulation if the material is carefully pressed by around 10% upon installation.

Vermiculite is an environmentally-friendly product which

can be returned to nature as a recyclable material.

Vermiculite is an important basic module in

the Building industry , in

Industry , in Fire protection ,

in Gardening and in

Animal care .

Areas of application

The usual application areas for vermiculite in a loose

bulk:

As insulation in structural engineering, as back

insulation in industrial furnace construction and as a cover

mass in the iron and steel industry. An interesting use of

vermiculite is in cast moulding for slow, targeted cooling of

larger moulded parts.

Vermiculite has an impact absorbing effect as a light, compressible bulk product. Together with huge absorption capacity, vermiculite is the perfect packaging aid for both dangerous liquids and goods as risk of impacts. Due to this distinctive absorption effect, vermiculite is particularly suitable as a binder for aggressive chemicals and solvents.

Chemical average analysis

| SiO2 | 35-41% |

|---|---|

| P2O5 | 0,2-2% |

| Al2O3 | 6-9,5% |

| Li2O | 0,03% |

| TiO2 | 0,6-1,4% |

| ZrO2 | traces |

| Fe2O3 | 6-9,5% |

| Cr2O3 | 0,01-0,15 |

| Na2O | 0,80% |

| F | 0,2-0,8% |

| K2O | 3-6% |

| SO3 | 0,02% |

| S | 0,18% |

| H2O + 105 C | 5,18% |

| Cl | 0-0,5% |

| H2O | 105 C 6,02% |

| FeO | 1,17% |

| NiO | traces |

| V2O3 | traces |

| MuO | 0,30% |

| MgO | 21,5-25,5% |

| CoO | traces |

| CaO | 2-6% |

| BaO | traces |